How Did They Build That? Seagram Building New York City

Our most common, modern-day building designs all started from an original idea by someone unafraid to try something new. Without the early architects’ visionary and creative ideas, and the structural engineers willing to try them, our country’s most famous skylines would look vastly different today, perhaps even be indistinct from each other.

Don't have time to read the article? Scroll down to watch a video on the making of the Seagram Building.

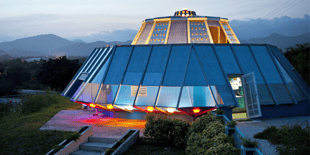

If you aren’t a New Yorker or familiar with New York City architecture, without knowing its history, you probably wouldn’t give the building that sits at 375 Park Avenue in Midtown Manhattan, New York City, a second glance. With its modest 515-feet height (relatively speaking) and nondescript facade, nothing in particular about the building (today) stands out. Or maybe…just maybe…you might notice the unique deep bronze and taupe color of the building.

You wouldn’t guess that at one time, this building was hailed as “the most beautiful tower ever to rise on the Manhattan skyline.” For those of you who know the history of this building, know that it is one of the great American construction marvels, an architectural icon, and a New York City landmark.

This building is the Seagram Building, home of the Canadian distillers U.S. subsidiary Joseph E. Seagram & Sons from 1954 to 2001, whose headquarters was the flagship of the building.

The Project

The Seagram was the first office building to use extruded bronze on the façade.

The Seagram was the first office building to use extruded bronze on the façade.In June 1934, not long after the end of Prohibition, Seagram moved its U.S. subsidiary, Joseph E. Seagram & Sons, Inc. into the Chrysler Building. But as the alcohol empire grew, the need for a bigger office grew as well. The company began a years-long search of where to move to accommodate this growth. When it was finally decided that the company would purchase land and build, Seagram’s founder, Samuel Bronfman, sent the building’s original plan to his daughter, Phyllis Lambert.

Phyllis was working as an artist in Paris when she received the letter from her father. She writes she found the plans “horrifying.” She wrote back to her father passionately opposing the design. Phyllis began the search to find a different architect who would match the vision the family wanted for the building, one that would reflect the brand's standards. She chose German-born American architect Maria Ludwig Michale Mies/Ludwig Mie van der Rhoe, referred to as Mies.

Mies was not licensed in New York, so Philip Johnson, another modernist architect, served as co-architect, along with Ely Jacques Kahn and Robert Allan Jacobs as associate architects.

A founding father of modernist architecture, Mies' philosophy was “less is more.

A founding father of modernist architecture, Mies' philosophy was “less is more.Ludwig Mies van der Rohe

Mies is considered one of the founding fathers of the International Style of architecture. Born in Germany and later immigrating to the U.S., Mies was the last director of the famous German art school, Bauhaus. He did not like ornamentation on buildings and favored simplistic and efficient styles and using new materials. He often described his style as “less is more.”

The Construction

The Seagram was “One of the biggest engineering projects in American history” -Procore

Construction on the Seagram building began in 1955. It is built on a steel frame with a structural system consisting of steel columns. With 38 stories, concrete core shear walls extend up to the 17th floor and diagonal core bracing from there to the 29th floor.

Mies wanted the building’s steel structure visible; however, the building code required it to be covered in fireproof material, so they covered the frame in concrete and gypsum. To realize his vision of having the frame visible, he used bronze-colored mullions instead. Each bronze mullion measures 26’ and was the longest bronze sections ever extruded at that time. The Seagram was the first office building to use extruded bronze on the façade. According to Architectuul.com, “This method of construction using an interior reinforced concrete shell to support a larger non-structural edifice has since become commonplace.” (Seagram Building | Architectuul)

The Seagram’s steel beam skeleton is held together by 190,000 high-tensile bolts, which were not riveted as is the most common practice, but were bolted to reduce noise. It took over 700 construction workers to fit the over 5,000 steel pieces together—a total of 25 million pounds of steel.

The Plaza

The Seagram building purposely sits back 100 feet from the street—unheard of at the time—to accommodate the pedestrian plaza in the front of the building. Slightly raised above sidewalk level and made of pink granite and featuring imported Italian marble seating and two large pools, the Seagram plaza helped influence the 1961 Zoning Resolution in New York City. Further, an internal heating system under the plaza can melt up to 500 tons of ice a day.

The New York City 1961 Zoning Resolution

The first resolution to pass since NYC’s first zoning code in 1916, the 1961 Zoning Resolution provided incentive zoning for buildings to incorporate public plazas in their design.

Phyllis Lambert writes, “On the positive side, the Seagram building and plaza prompted a revision of the city’s zoning ordinance that ushered in incentive zoning to encourage the development of open public space at street level; on the negative side, the city levied special taxes on the property because the building did not occupy the maximum extent of its site, and at the same time questioned the company’s motivation for erecting a structure so much more costly than the ordinary commercial office building.”

The Glass Windows

The color of the glass windows on the Seagram Building was chosen to deepen in color over time. (photo courtesy of Tom Ravenscrodt

The color of the glass windows on the Seagram Building was chosen to deepen in color over time. (photo courtesy of Tom RavenscrodtThe Seagram Building features floor to ceiling windows—the first tall building in New York City to have “full-height plate glass windows.” (Wikipedia) Mies picked the whiskey-colored glass so that it would deepen over time but also retain the rich color. There are 122,000 square feet of glass panels in the Seagram, all permanently sealed and treated for heat and glare resistance.

On Mies's insistence to maintain the building’s consistent appearance, the blinds covering the windows at Seagram Building only open three ways—fully open, halfway open, and fully closed.

Completed Construction

Construction on the Seagram was completed in 1958. Finishing touches on the inside included expensive marble and travertine. The Bronfman’s spared no expense or luxury, installing an electrostatic air filtration system and incorporated a modern parking garage.

In the same year, the Seagram was finished, Progressive Architecture described it as “probably the most heralded new building in the U.S.”

The structural engineers for Seagram Building, Severud Associates write, “…the Seagram Building was one of the first tall buildings to use a vertical truss bracing system” and that the Seagram “became a prototype for high-rise buildings around the world.”

In the end, the final cost of the project was about $40 million, making it the most expensive skyscraper project at the time.

In 1979, Seagram sold the building to the Teachers Insurance and Annuity Association for $85.5 million but kept its headquarters there until 2001.

Awards

- Fifth Avenue Association award for best building constructed on Park Avenue 1956-1957

- Board of Trade architecture prize 1963

- Municipal Art Society bronze landmark plaque 1967

- American Institute of Architects (AIA)recognition 1979

- AIA Twenty-Five Year Award 1984

- Added to National Register of Historic Places 2006